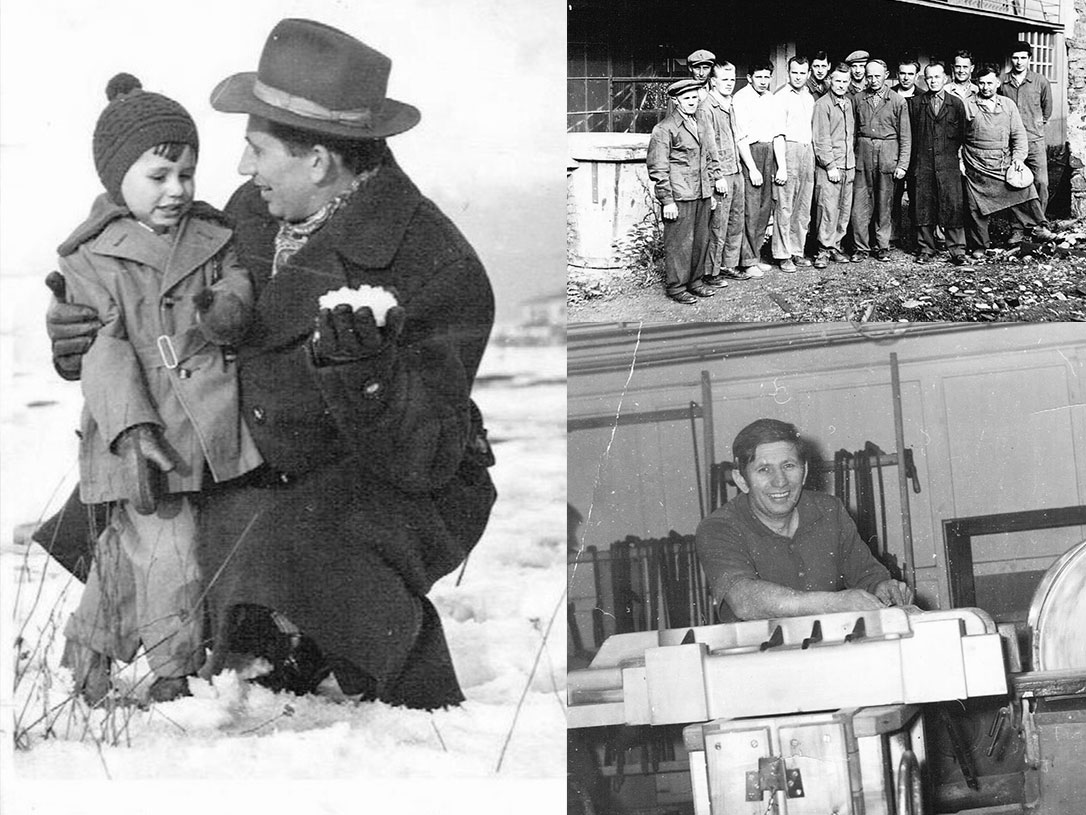

ABOUT THE

MODELÁREŇ S.R.O. COMPANY

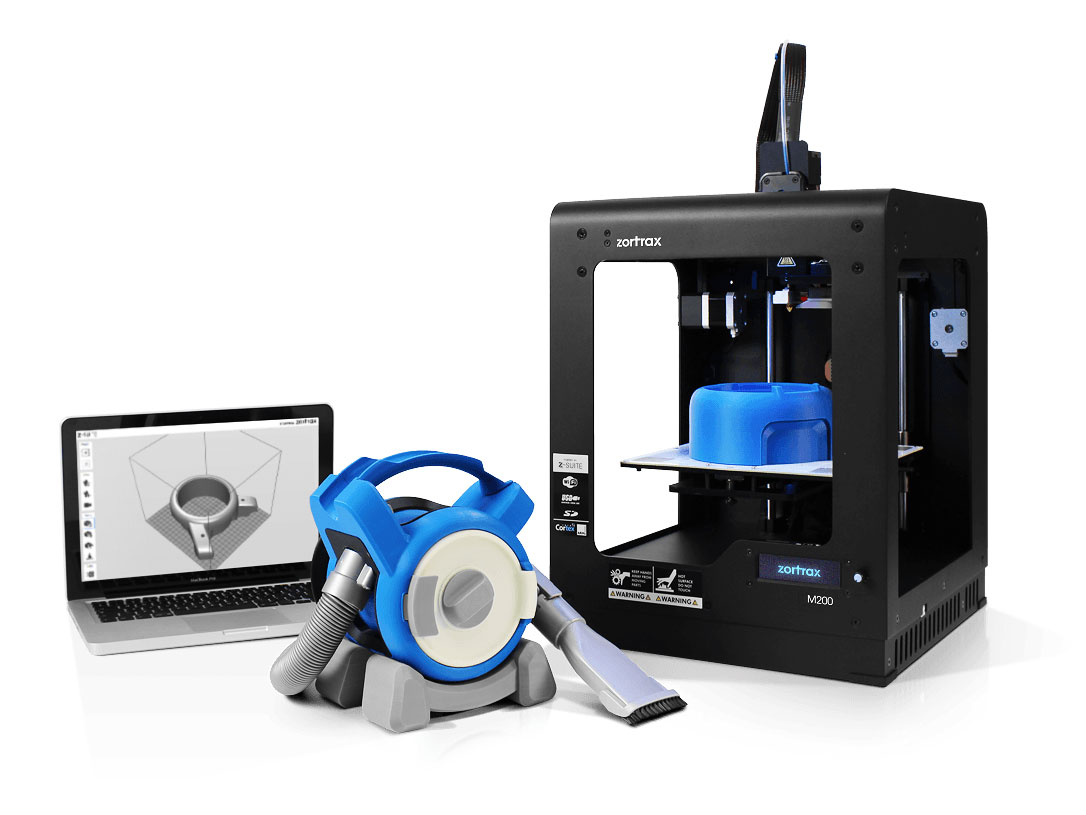

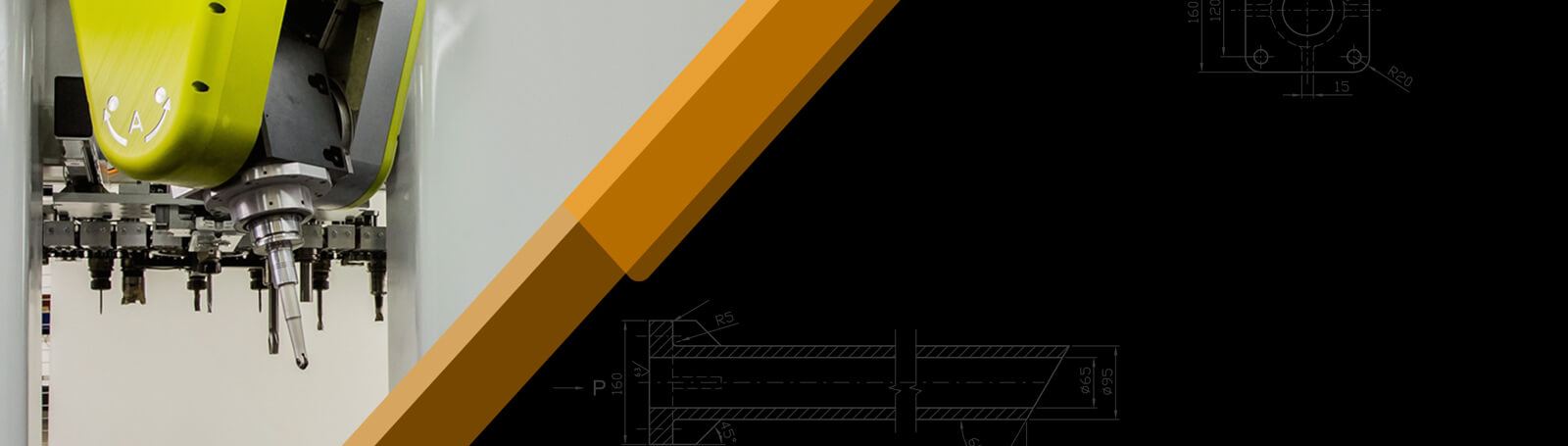

The Modeláreň s.r.o. company operates in the area of the production of single-part and serial pattern devices, moulds, composites, as well as of the comprehensive deliveries of final products, including all manufacturing steps. Our manufacturing processes contain the up-to-date technologies - from CAD/CAM programming, engineering, 5-axis CNC milling and 3D print to 3D scanning.

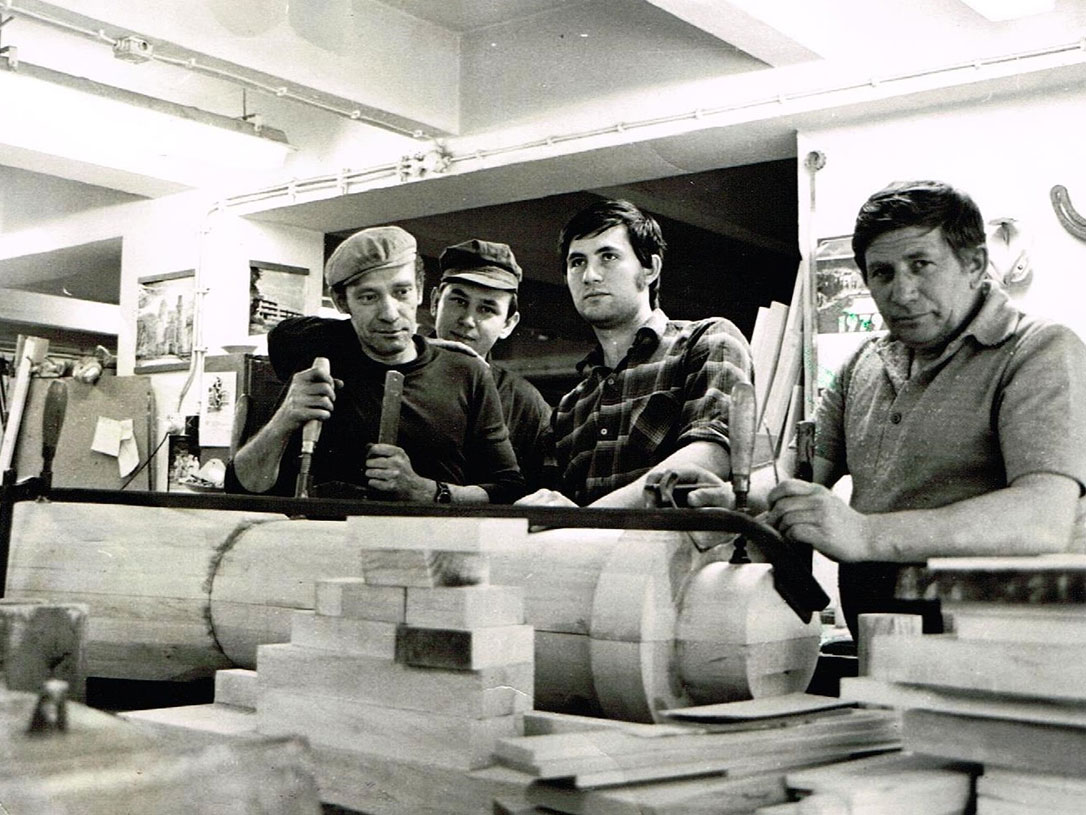

We are able to react promptly and flexibly to all wishes and needs of our customers. Long-term skills and professional knowledge of our employees are the conditions for the production of precision pattern devices, moulds or castings.

Certificate ISO:

To maintain confidence of our customers we guarantee high quality of our products and reliability of our services.